Traditional RV Construction:

In the RV market there are 2 main ways that trailers have been constructed: “Stick and Tin” and Fiberglass. Stick and Tin trailers use a wooden frame and corrugated aluminum shell in their construction. Aluminum and Fiberglass constructed trailers, on the other hand, utilize an aluminum frame with varying types of laminated fiberglass for its walls (For more information, read this article comparing the two: Stick and Tin vs Aluminum and FIberglass). RVs of these two construction methods dominate the market because they are effective construction methods.I’ll say it again, there is nothing wrong with the traditional construction methods. People much smarter than me will confirm that. Engineers have been designing them for a long time and you will find high-quality trailers constructed using either method. But like anything else, there are some drawbacks and room for improvement.

That’s where TransCore comes in.

- Stick and Tin trailer with corrugated aluminum sides

- Typical Fiberglass trailer

A New Way of Building Trailers with Structural Composite

Transcore built by Ridge Corporation

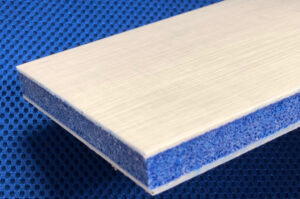

Transcore is an engineered thermoplastic composite sandwich panel that is abrasion and puncture resistant. The panel is engineered with high glass content skins that are thermally fused to a resilient thermoplastic core which provides an optimized structure to provide durability and stiffness at the lowest weight possible. This weather resistant composite panel is hydrophobic and resists corrosion and protects from mildew and degradation.

We discovered TransCore through the Palomino Pause, a unique Off-Road, Off-Grid trailer sold at ROA Off-Road. Impressed by its features, we delved into factory tours and off-road adventures with the manufacturers.. With that said, all of our experience with TransCore is based on the real-world camping experience that we have using a trailer where the floor, sides, and ceiling are 1-piece TransCore structural composites.

We discovered TransCore through the Palomino Pause, a unique Off-Road, Off-Grid trailer sold at ROA Off-Road. Impressed by its features, we delved into factory tours and off-road adventures with the manufacturers.. With that said, all of our experience with TransCore is based on the real-world camping experience that we have using a trailer where the floor, sides, and ceiling are 1-piece TransCore structural composites.

Bio-Stat Technology, UV Resistance, and Increased Trade-In Value

One of the major enemies of traditional trailers is rot. Rot will begin without you even knowing in inaccessible parts of your trailer. You only notice when your wall, floor or ceiling caves in revealing that you’ll need to replace large sections or an entire side panel. TransCore’s Bio-Stat Technology is the anti-microbial and antifungal quality of the trailer. It protects your trailer from rot because its not organic! TransCore improves the integrity of your trailer, making it safer and guarteeing a longer life. On Our TransCore representative, the Pause by Palomino this is doubly the case because on the entire trailer, there isn’t a scrap of wood! Even the cabinets are made of aluminum so that rot and replacement are never a concern. Amazing, right?

We’re all familiar with the damage that UV rays can do to our homes, cars, and trailers. TransCore’s UV Resistant properties hold up preserving its color and quality.

With TransCore’s UV-Resistance and BioStat Technology on a trailer, you should feel that you’re purchasing something you might be able to hand off to your children. It’s going to last a while! With UV-Resistance and BioStat Technology, a TransCore trailer could become a lasting possession, maintaining its value better during resale or trade-in.

TransCore is an Amazing Insulator

One brand of trailers that features TransCore is the Palomino Pause brand. Palomino uses the Transcore for its floors, walls, and ceiling. We have spent a lot of time in the Pause trailers in the snowy mountains of Utah and in the scorching heat of the Nevada desert and we can testify that the Transcore material is an amazing insulator. Watch this video on our trip to Las Vegas in the Palomino Pause on YouTube. It was 100+ degrees in Las Vegas, and thanks to its TransCore siding, flooring and roofing the Palomino Pause was able to easily maintain a comfortable temperature. Some parts of the outside of the trailer reached up to 150F, while the inside remained nice and cozy.

TransCore is Lightweigh and Incredibly strong

And the Transcore is SO LIGHT! We were able to take a tour of the Palomino Pause factory and watch as they installed the walls on a new Pause XC21.3. A team of 2 men easily lifted and installed the siding for a 21ft long off-road trailer. We were blown away. As a team of 5 lifted and set the TransCore floor piece in place, we couldn’t believe how it maintained its shape. TransCore structural composite can achieve feats that plywood and most fiberglass can’t even dream of. Not only is it light, the TransCore is TOUGH beyond belief!

Impact-Resistant TransCore

While ROA’s Marketing Team was on a tour of the Palomino Pause factory in Elkhart, IL, they were invited to test out the strength of the TransCore siding. The production manager at the factory handed our CEO, Shane, a sledgehammer and dared him to try to break a piece of TransCore paneling. Now, Shane is a big guy. Standing over 6 feet tall and weighing over 200 lbs, he is no feather-weight. The paneling refused to even dent after a few gentle swings. Surprised, he started to swing as hard as he could, but even after pounding on the panel with all of his strength, the panel emerged victorious! Watch the video on YouTube here. This is perhaps the most impressive quality of the TransCore paneling. When it comes to constructing trailers, TransCore stands head and shoulders above anything else in the RV industry. There is no trailer on the market that can withstand any number of blows from a sledgehammer. The TransCore beats a sledgehammer!

I hope that by now you can see why we’re so amazed by TransCore. TransCore’s remarkable qualities extend beyond what we’ve covered. For more information and insights, visit RidgeCorporation’s website to explore their advancements in structural composites.

I hope that by now you can see why we’re so amazed by TransCore. TransCore’s remarkable qualities extend beyond what we’ve covered. For more information and insights, visit RidgeCorporation’s website to explore their advancements in structural composites.

Happy Camping! 🙂